Automatic Weighing and Packaging Machines: Complete Buying Guide with Features and Applications

In today’s fast-paced manufacturing world, precision, speed, and automation are critical to staying competitive. Automatic weighing and packaging machines have become essential tools for companies aiming to improve efficiency, reduce waste, and deliver consistent quality. Whether you're packaging snacks, powders, chemicals, or medical products, these machines can significantly enhance your production capabilities.

In today’s fast-paced manufacturing world, precision, speed, and automation are critical to staying competitive. Automatic weighing and packaging machines have become essential tools for companies aiming to improve efficiency, reduce waste, and deliver consistent quality. Whether you're packaging snacks, powders, chemicals, or medical products, these machines can significantly enhance your production capabilities.

In the following sections, we’ll explore key components, features, industry applications, and tips for choosing the right solution for your business.

What Is an Automatic Weighing and Packaging Machine?

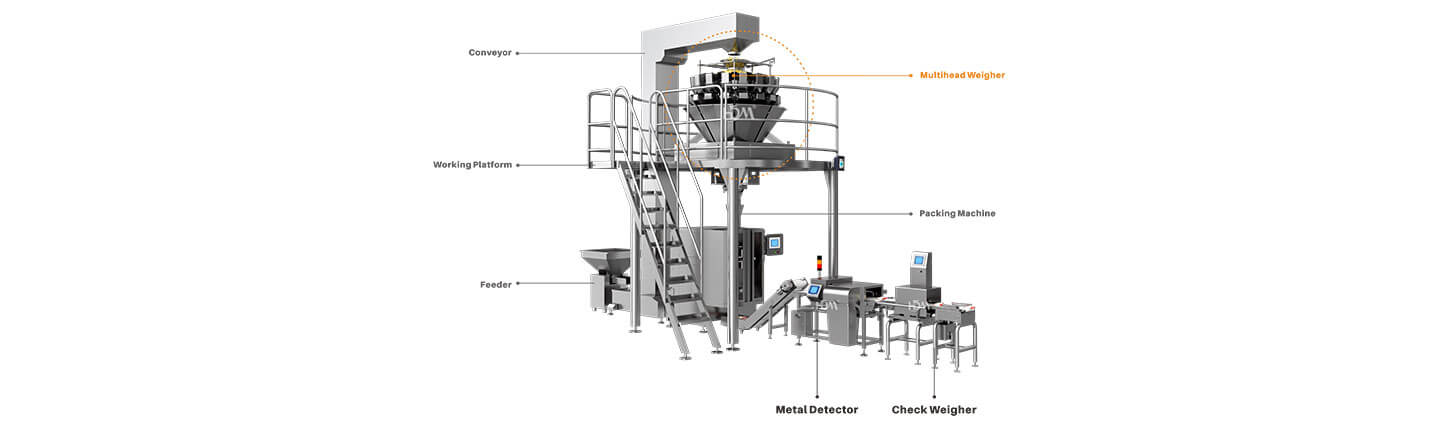

An automatic weighing and packaging machine is an integrated system designed to weigh products accurately and pack them into containers or bags without manual intervention. It typically includes a feeding system, multihead weigher, packaging machine, and quality control systems such as check weighers, metal detectors. This system is ideal for high-throughput production lines that require strict accuracy and consistent output.

For more on how smart weighing technology can improve precision, see our detailed guide on Combination Scales.

Introduction of Automatic Weighing and Packaging Machine Specifications

Automatic weighing and packaging machines are available in a variety of models tailored for different product types, speed requirements, and precision levels. Below are some general technical specifications:

-

Weighing Range

: Typically from 0.5 gram up to 5 kilograms depending on the machine configuration -

Weighing Accuracy

: High-precision models such as the Super Precision Micro Weigher achieve ±0.03 g, while standard multihead weighers typically range from ±0.1 g to ±2 g—select the tolerance that fits your product’s weight, size, flow characteristics and allowable giveaway. -

Speed

: Depending on product flow and packaging format -

Number of Heads (Multihead Weighers)

: 10-head, 14-head, 16-head, and up to 30-head configurations available -

Supported Packaging Types

: Pouch, pillow pack, tray, canister, shrink wrap, and vacuum sealing -

Integration Compatibility

: Seamlessly integrates with VFFS (Vertical Form Fill Seal), HFFS (Horizontal Form Fill Seal), premade pouch fillers, and conveyor systems

Key Components and How They Work

-

Feeding and Conveyor System

The feeding unit ensures steady and even flow of products to the weigher. Vibratory or belt conveyors are commonly used for different product types.

-

Multihead Weigher

At the heart of the system, the multihead weigher uses multiple weighing buckets to find the optimal combination of weights, ensuring accuracy down to the gram.

Compared to linear weighers, multihead weighers offer significantly faster operation and higher accuracy by combining multiple weight combinations in real time. While linear systems are more cost-effective for simple, low-speed applications, they’re best suited to free‑flowing granules and small solids. Multihead weighers, by contrast, handle a broader range of products—from powders and snacks to frozen items—making them ideal for high‑volume, precision‑critical production. -

Packaging Machine

From pillow packs and trays to vacuum or shrink packaging, this module handles the sealing, cutting, and labeling processes.

-

Detection & Quality Control

Built-in metal detectors and check weighers remove contaminated or misweighed items, maintaining packaging consistency and safety.

Top Benefits of Using Automatic Weighing and Packaging Machines

- High-precision weighing reduces product giveaway and ensures every package meets the required weight.

- Automating the process lowers labor costs and minimizes manual errors.

- Faster throughput supports large-scale production demands.

- Real-time data and smart control systems help improve operational efficiency and reduce downtime.

- Flexible systems can handle powders, granules, snacks, seafood, pharmaceuticals, and more.

These benefits are not limited to one field—they extend across a wide range of industries with varying production needs.

Applications Across Industries

-

Food Industry

From chips and candies to frozen dumplings and spices, these machines ensure hygienic, accurate, and fast packaging.

In the snack sector, automatic systems are often integrated with fast multihead weighers and pillow-type packagers to handle high volumes of chips, nuts, and candies. For frozen foods like dumplings or seafood, vacuum packaging is paired with stainless steel-grade conveyors for hygiene compliance.

-

Chemical Products

Suitable for fertilizers, cleaning powders, and industrial additives—especially those needing dust-free, secure packing.

-

Pharmaceutical Products

Guarantees precise dosage per pack for capsules, powders, and blends, reducing compliance risks.

-

Cannabis Products

Supports accurate dosing and secure packaging for flower, gummies, pre-rolls, and seeds—ensuring regulatory compliance.

-

Electronics & Hardware

Perfect for sorting and weighing small components like screws, sensors, or other precision items.

How to Choose the Right Automatic Weighing and Packaging Machine

-

Product Compatibility

– Is it designed for your specific product type (powder, granule, solid)? -

Speed and Accuracy Requirements

– Match throughput needs without sacrificing weight precision. -

Packaging Style Needs

– Tray, pillow, shrink wrap, or vacuum options based on market.

The machine supports various packaging styles depending on product type and market needs. Common formats include tray packaging for fragile or fresh produce, pillow packs for snacks, vacuum packaging for perishable goods, and shrink wrapping for retail-ready presentation.

-

System Integration

– Can it connect with your existing production line?

Integration into existing production lines is straightforward with High Dream systems. Our machines support modular installation, PLC compatibility, and customizable interfaces—making them easy to fit into both new and legacy setups.

-

After-Sales Support

– Ensure technical support and easy maintenance are available.

The machine supports various packaging styles depending on product type and market needs. Common formats include tray packaging for fragile or fresh produce, pillow packs for snacks, vacuum packaging for perishable goods, and shrink wrapping for retail-ready presentation.

Integration into existing production lines is straightforward with High Dream systems. Our machines support modular installation, PLC compatibility, and customizable interfaces—making them easy to fit into both new and legacy setups.

Common Customer Questions and Challenges

Beyond technical features, many businesses have recurring concerns when evaluating their investment.

Many clients often ask:

- "Which machine is best for sticky or fragile products?"

- "Can your system handle both small retail pouches and large bulk packaging?"

- "How easy is it to clean and switch between product types?"

High Dream designs solutions with these challenges in mind. Our conveyorized systems are suited for difficult-to-move items, while toolless designs reduce downtime between product changeovers.

Why Choose High Dream’s Weighing and Packaging Solutions?

At High Dream, we offer more than just machines—we deliver full-system solutions. From professional solution planning and model selection to installation and lifetime service support, we guide our clients every step of the way.

-

Labor-Saving Efficiency

– Reduce operational overhead through automation. -

Robust and Reliable

– Tested for harsh conditions to minimize downtime. -

All-in-One Integration

– Our packaging lines span weighing, filling, sealing, metal detection, and inspection. -

Continuous Innovation

– We adapt our technologies to meet changing industry needs. -

Premium Customization

– We tailor each system to the customer’s exact specifications.

Let’s Build Your Automated Packaging Line Together

Need help choosing the right model or configuration? Contact the High Dream Experts and discover how our solutions can maximize your output and minimize costs.